Next Generation of Ice Making:

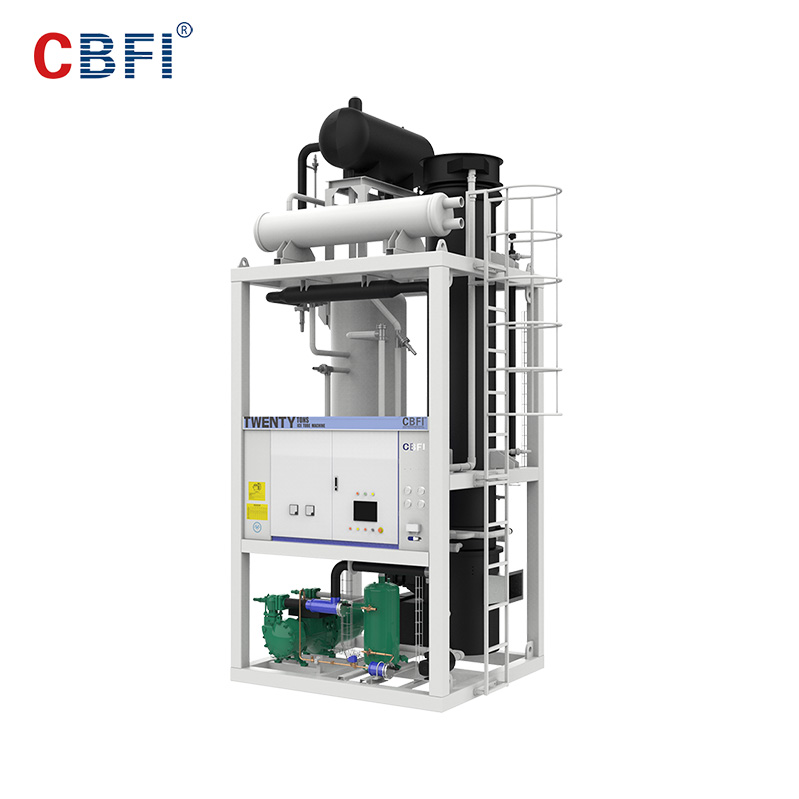

The Integrated 20-Ton Per Day Tube Ice Machine

The integrated tube ice machine is an innovative industrial ice-making equipment designed specifically for large-scale commercial ice block production environments. It adopts advanced international refrigeration technology and intelligent control systems, enabling fast and efficient production of edible ice blocks, while also featuring energy conservation, environmental friendliness, and ease of operation.

Why Choose CBFI® Ice Tube Machine

Quick Installation

Just connect water and electricity to produce

Reduces on-site installation complexity about save a week of installation and debugging time

Steady Running

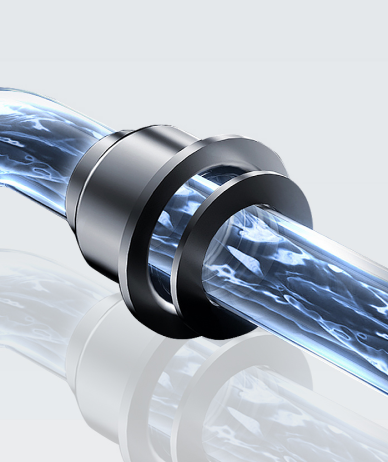

Newly Upgraded Ice Cutting Mechanism

Scientifically designed speed and shock absorption ensure long-term stability even during high-speed operation

Extremely uniform minimal ice breakage

Uniform ice helps increase productivity and reduce losses

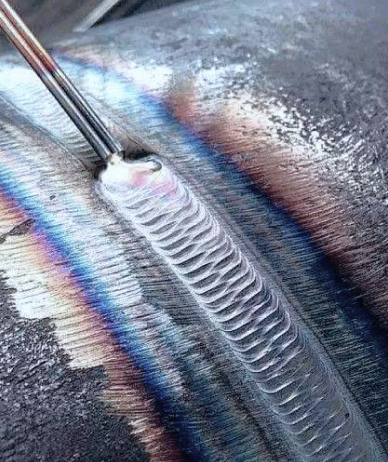

Special layered design

High-precision intelligent mechanical welding

Welding process system

Advantages of The CBFI Tube Ice Machine

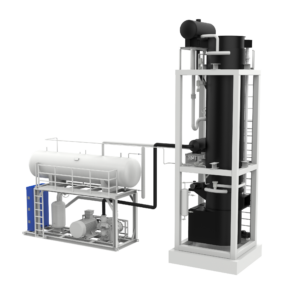

Saves approximately 40% space compared to a 30-ton split tube ice machine with the same configuration by CBFI.

Compact design with a small footprint and low operational noise, suitable for various sizes of commercial spaces.

Reduced floor space and saved freight.

Energy-saving Design

Continuous investment in research and optimization of technologies, including flat wall heat exchange and cyclic hot gas ice harvesting.

The equipment is equipped with easy-to-use ladders for convenient daily inspection and maintenance by staff.

The layout of wires and pipelines is rational, with adequate protective measures in place to ensure operational safety while enhancing the equipment’s aesthetics.

1. Smart System Simulation – Real-time visual monitoring of operations with immediate alerting in case of anomalies.

2. Intelligent Fault Diagnosis and Repair Guidance – Instant fault warnings and access to troubleshooting methods.

3. Comprehensive Safety Mechanism – Multiple automatic protection systems and foolproof design.

4. EU Certified Safety and Quality – Compliant with CE standards for electrical circuits and safety switches.