This hardness tester has a novel appearance, complete functions, convenient operation, clear and intuitive display, and stable performance. It is a high-tech product that integrates mechanical, electrical, and optical testing. It can be tested using three testing methods: Brinell, Rockwell, and Vickers.

This hardness tester has a novel appearance, complete functions, convenient operation, clear and intuitive display, and stable performance. It is a high-tech product that integrates mechanical, electrical, and optical testing. It can be tested using three testing methods: Brinell, Rockwell, and Vickers.

1. he body part of the product is formed in one go through a casting process and has undergone long-term aging treatment. Compared to the panel assembly process, long-term use has minimal deformation and can effectively adapt to various harsh environments;

2. Automotive paint, with high quality and strong scratch resistance, remains shiny and new after years of use;

3. Ready to use upon startup, without the need to install weights;

4. It adopts a large screen touch LCD display interface, with rich display content and convenient operation;

5. The electronic closed-loop control applies the test force, with an accuracy of 5 ‰. The force sensor controls the test force, fully realizing the automatic operation of applying, maintaining, and removing the test force;

6. The hardness values of each scale can be converted to each other through measurement;

7. The body is equipped with a micrometer and a high-definition micro optical system to make the observation readings clearer and reduce errors;

8. Equipped with a built-in micro printer and optional RS232 data cable, it can be connected to the computer through a super terminal to export measurement reports.

9. Equipped with three testing methods of Brinell, Rockwell, and Vickers, with multi-level testing force, it can meet various hardness testing requirements;

Standard configuration:

|

Name |

Quantity |

Name |

Quantity |

|

Hardness tester host |

1 |

Diamond Rockwell indenter |

1 |

|

Diamond Vickers indenter |

1 |

φ1.5875mm ball indenter φ2.5mm ball indenter φ5mm ball indenter |

Each 1 |

|

HRC standard hardness block |

3 |

Allen key 2.5MM |

1 |

|

HRB standard hardness block |

1 |

big、small、V-shaped sample stage |

Each 1 |

|

HRA standard hardness block |

1 |

External lighting |

1 |

|

HVstandard hardness block |

1 |

Slide sample table |

1 |

|

HB standard hardness block |

1 |

Microscopium (including interior lamp) |

1 |

|

Horizontal adjustment screw |

4 |

Level gauge |

1 |

|

Digital micrometer eyepiece |

1 |

2.5X、5X、10X objective |

Each 1 |

|

Power line |

1 |

Fuse 2A |

2 |

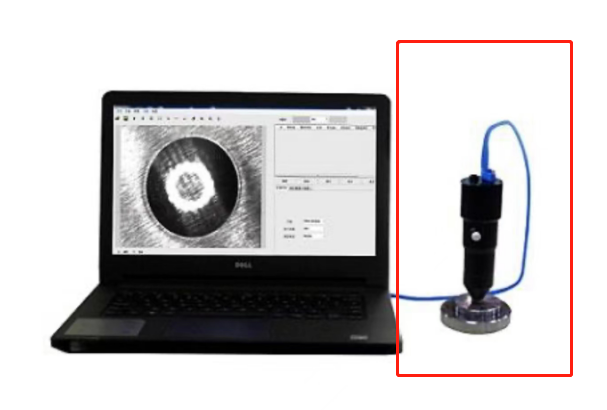

Brinell Camera

equipped with USB camera, laptop and data read and write software

USB digital microscope:

Excellent image quality

USB 2.0 connection

Measurement ranges: 2.4 – 6 mm

Brinell Magnifier 20x

20x magnification

Measurement range: 2.4 – 6 mm

Resolution 0.05 mm

Application scope:

Suitable for measuring the hardness of quenched, tempered, annealed, cold hard castings, malleable castings, hard alloy steel, aluminum alloy, copper alloy, bearing steel, etc.

Technical parameters:

|

Rockwell Scales |

Initial Testing Force |

10kg(98.07N) |

|

Total test force |

60、100、150Kgf (588、980、1471N) |

|

|

Indenter |

Diamond Rockwell indenter、Ф1.5875mm Ball indenter |

|

|

Scales |

HRA、HRB、HRC、HRD、HRE、HRF、HRG、HRH、HRK、HRL、HRM、HRP、HRR、HRS、HRV |

|

|

Maximum height of the specimen |

180mm |

|

|

Brinel Scales |

Testing Force |

5、6.25、10、15.625、30、31.25、62.5、 100、125、187.5、250Kgf |

|

Scales |

HBW1/5、 HBW2.5/6.25、 HBW1/10、HBW2.5/15.625、HBW1/30、HBW5/31.25、HBW2.5/62.5、HBW5/62.5、HBW10/100、HBW5/125、HBW2.5/187.5、HBW5/250 |

|

|

Indenter |

φ2.5mm、φ5mm Ball indenter |

|

|

Eyepiece magnification |

15X |

|

|

Objective magnification |

2.5X、5X |

|

|

Maximum height of the specimen |

165mm |

|

|

Vickers Scales |

Testing Force |

5、10、20、30、40、50、60、80、100、120Kgf |

|

Indenter |

Diamond Vickers indenter |

|

|

Scales |

HV5、HV10、HV20、HV30、HV40、HV50、HV60、HV80、HV100、HV120 |

|

|

Eyepiece magnification |

15X |

|

|

Objective magnification |

10X |

|

|

Maximum height of the specimen |

165mm |

|

|

Hardness tester host |

Display method |

LCD digital display |

|

Distance from the center of the pressure head to the body |

160mm |

|

|

External dimensions of hardness tester |

550*230*780mm |

|

|

Instrument weight approximately |

80KG |

|

|

Auxiliary functions |

Storage function; Built in printer; Hardness conversion between different hardness scales |

|

|

Interface |

RS232 |

|

|

supply voltage |

AC220V±5%,50~60Hz |